ECOLOFLEX SPC HyB

ECOLOFLEX SPC HyB

The Original TBT-free SPC

ECOLOFLEX SPC HyB

The Original TBT-free SPC

DOWNLOAD DOCUMENTATION

OVERVIEW

Nippon Paint Marine have a long and proud history of dedicated and detailed research and development into antifouling paints that have reduced shipping's marine environmental impact and in reducing air pollution.

In 1991, Nippon Paint Marine developed the world’s first TBT-free true self-polishing copolymer (SPC) antifouling “ECOLOFLEX” series. ECOLOFLEX products have been applied to many thousands of ships and continue to reduce shipping’s costs and environmental impact to this day.

ECOLOFLEX SPC HyB is the latest and ultimate version of Nippon Paint Marine’s SPC range and has demonstrated ultra-reliability on ships operating in all areas of the world. By keeping ships clean reliably, ECOLOFLEX products provide predictability and keep owners and charterers’ fuel costs down.

Key Features

Fouling protection. Long term operation. Smoothing & roughness control

Applicable to various types of ships.

Standard practice & apparatus.

FEATURES

ECOLOFLEX provides proven protection from fouling.

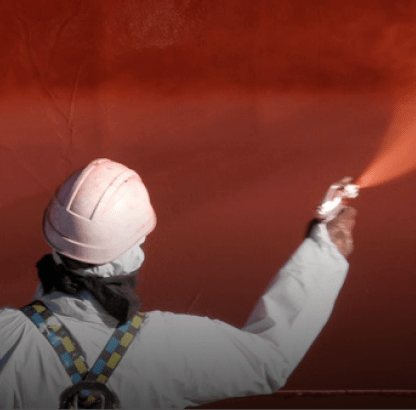

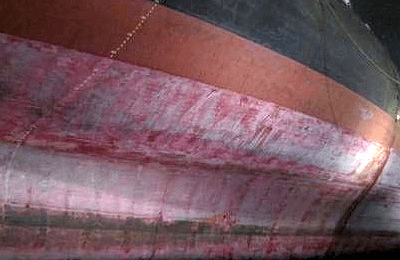

These ships arrived in drydock after operation with ECOLOFLEX showing excellent performance. All photos are taken before any High-pressure washing was done. The sprayer’s pattern is clearly shown showing ECOLOFLEX’s reliable self-polishing.

VLCC (314,079 DWT) , 16 knots, 30M

VLCC (298,414 DWT) , 16 knots, 60M

LNG (69,594 DWT) , 16 knots, 30M

LNG (63,510 DWT) , 16 knots, 30M

BC (56,000 DWT) , 15 knots, 60M

CERTIFICATION

ECOLOFLEX series complies with IMO-AFS2001 as tin-free anti-fouling system. Certification from Classification Societies is available.

- JPMA (Japan Paint Manufactures Association)

- DNV-GL

- Lloyd’s Register

- Korean Register

Consult with your local Nippon Paint Marine representatives for more details.

PRODUCT RANGE

The Original TBT-Free SPC

• Nippon Paint’s Hydrolysis SPC Technology

• Wide Protection Range

• Good Workability

Advanced Copper Silyl-acrylate SPC

• Nippon Paint’s Hydrolysis SPC Technology

• Good Workability

The Original TBT-Free SPC

• Nippon Paint’s Hydrolysis SPC Technology

• Wide Protection Range

• Good Workability

The Original TBT-Free SPC

• Nippon Paint’s Hydrolysis SPC Technology

• Good Workability

The Original TBT-Free SPC

• Nippon Paint’s Hydrolysis SPC Technology

• Wide Protection Range

• Good Workability

The Original TBT-Free SPC

• Nippon Paint’s Hydrolysis SPC Technology

• Good Workability

The Original TBT-Free SPC

• Nippon Paint’s Hydrolysis SPC Technology

• Good Workability