LF-SEA

LF-SEA

Bright Futures begin with Clean Oceans

LF-SEA

Bright Futures begin with Clean Oceans

DOWNLOAD DOCUMENTATION

OVERVIEW

The World's First True Low-Friction Antifouling Paint

A biomimetic low-friction antifouling that works using Nippon Paint Marine’s patented water trapping function to lower the hydrodynamic footprint of the hull. Stable and long term fouling prevention is guaranteed by using Nippon Paint Marine’s most effective self-smoothing copper-silyl-acrylate copolymer antifouling paint.

The combination of the clean hull, accurate and predictable self-smoothing as well as the unique water-trapping technology gives a verifiable effect. This all combines to truly lower ships’ surface friction leading to verifiable fuel and CO2 emission savings.

Key Features

Long term and stable self-polishing

Smoother hull and super low friction

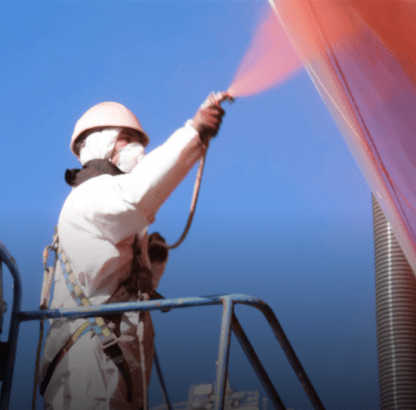

Applicable using standard practice and equipment

FEATURES

Water trapping technology

LF-Sea’s biomimetic technology was inspired from the skin of Tuna.

A specially formulated and unique hydrogel has been incorporated into Nippon Paint Marine’s ultra efficient copper silyl acrylate self-polishing antifouling paint. This hydrogel then creates a microscopic water-trapped layer at the interface between the paint film and the seawater.

Hydrogel technology and the water-trapping it creates, leads to a reduction of the ships’ frictional resistance.

APPLICATION

Applicable using standard practice and equipment. Direct application over existing antifouling. LF-Sea provide excellent anti-fouling performance.

Hull condition after 35 month service. BC (266,140 DWT) , 15 knots, 35M

CERTIFICATION

LF-Sea series complies with IMO-AFS2001 as tin-free anti-fouling system. Certification from Classification Societies is available.

- JPMA (Japan Paint Manufactures Association)

- DNV-GL

- Lloyd’s Register

- Korean Register

PRODUCT RANGE

Fuel-saving SPC Antifouling

• Copper Silyl Acrylate Copolymer

• Water Trapping Technology

• Easy Application

Fuel-saving SPC antifouling

• Copper Silyl Acrylate Copolymer

• Water Trapping Technology

• Easy Application

Fuel-saving SPC antifouling

• Zinc Acrylate Copolymer

• Water Trapping Technology

• Easy Application

Fuel-saving SPC antifouling

• Zinc Acrylate Copolymer

• Water Trapping Technology

• Easy Application

Fuel-saving SPC Antifouling

• Copper Silyl Acrylate Copolymer

• Water Trapping Technology

• Easy Application

Fuel-saving SPC antifouling

• Copper Silyl Acrylate Copolymer

• Water Trapping Technology

• Easy Application

Fuel-saving SPC antifouling

• Zinc Acrylate Copolymer

• Water Trapping Technology

• Easy Application

Fuel-saving SPC antifouling

• Copper Silyl Acrylate Copolymer

• Water Trapping Technology

• Easy Application