FASTAR

PRECISE • PREDICTABLE • PERFORMANCE

-

Nanotechnology

Biocide Control -

Hydrogel water

trapping technology -

Ultra

low friction

FASTAR

PRECISE • PREDICTABLE • PERFORMANCE

DOWNLOAD DOCUMENTATION

OVERVIEW

FASTAR, a proprietary antifouling coating that incorporates for the first time a hydrophilic and hydrophobic nano domain structure using unique nano technology.

The coating efficiently consumes biocides and provides excellent antifouling performance with its nano domain technology. FASTAR is a next-generation antifouling paint friendly to the marine environment and supports the efficient operation of vessels and the marine business.

Commitments of FASTAR

High volume solid at 59%, coverage up to 150 microns

Low dry film thickness relative to conventional self polishing copolymer-based antifouling paint

Up to 60 idling days & up to 90 months dry dock interval.

Energy Efficiency with low CO2 & low VOC

FEATURES

NANO-Technology

Self Polishing & Self Smoothing Anti-Fouling Paint with NANO-Technology. Combining both hydrophilic & hydrophobic in nano-structure.

- Maintaining precise, stable and sustainable antifouling performance

- Improved operational efficiency

- Environmental protection

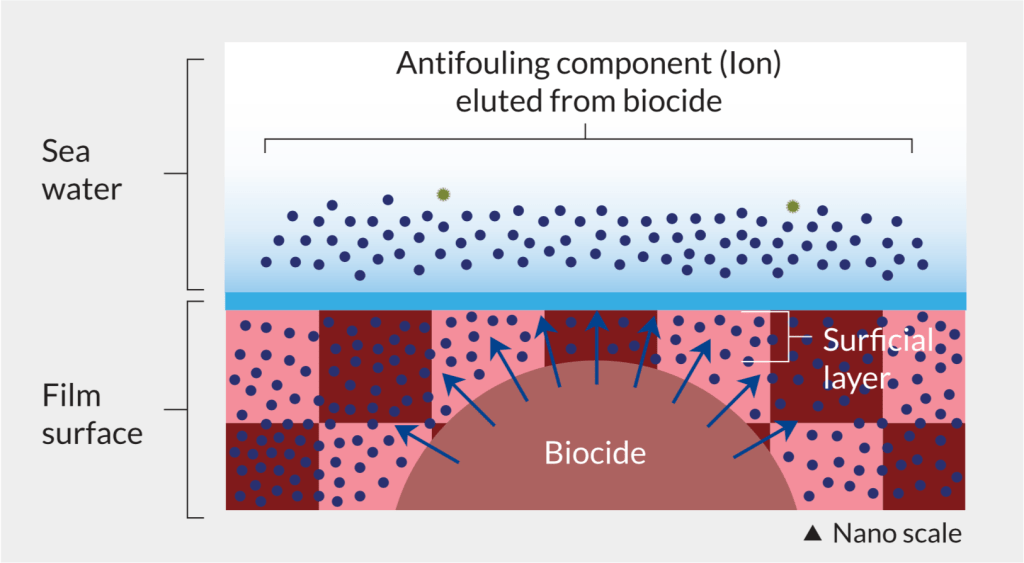

Focus on the surficial film of coating

To develop a new antifouling paint, Nippon Paint Marine adopted a method of modifying the surficial film of coating rather than selecting an biocides. Aiming for “higher antifouling performance”, our unique nanodomain technology is applied on the surficial film of the coating.

Control of elution of antifouling components

To develop the antifouling function, an antifouling component emitted from the biocides is required. The widespread and stable elution of antifouling components was made possible by the hydrophilic & hydrophobic nanodomain structure. That is, the antifouling component is diffused in the surficial film of the coating by the hydrophilic domain and retained by the hydrophobic domain, and is stably eluted over a wide range.

High Solid Content

Benefit

- Reduction of air pollution

- Improved coating efficiency

APPLICATION

Applicable with conventional painting methods and painting equipment. No special equipment required.

CERTIFICATION

FASTAR series complies with IMO-AFS2001 as tin-free anti-fouling system. Certification from Classification Societies & Paint association is available.

- JPMA (Japan Paint Manufactures Association)

- DNV-GL

- Lloyd’s Register

- Korean Register

SUSTAINABILITY

For the purpose of sustainable environmental protection, we created “water trapping technology” that enables low fliction and low fuel consumption with innovative technology.

From that point on, we also succeeded in developing an biocide free SPC coating with a “micro domain structure” with further innovative technology. Inspired by the technology cultivated with these antifouling paints, “FASTAR” aims at marine conservation and comfortable operation of ships, which will eventually lead to customer satisfaction and enrich our lives. It plays a role in realizing value creation.

We remain committed to ESG management of ship owners and ship builders through FASTAR.

PRODUCT RANGE

Nanodomain Structured Self-polishing Antifouling

• NANO-Technology

Nanodomain Structured Self-polishing Antifouling

• NANO-Technology

Nanodomain Structured Self-polishing Antifouling incorporating hydrogel for extra low-friction performance

• NANO-Technology

• Water Trapping Technology

Nanodomain Structured Self-polishing Antifouling incorporating hydrogel for extra low-friction performance

• NANO-Technology

• Water Trapping Technology

Nanodomain Structured Self-polishing Antifouling

• NANO-Technology

Nanodomain Structured Self-polishing Antifouling

• NANO-Technology

Nanodomain Structured Self-polishing Antifouling incorporating hydrogel for extra low-friction performance

• NANO-Technology

• Water Trapping Technology

Nanodomain Structured Self-polishing Antifouling incorporating hydrogel for extra low-friction performance

• NANO-Technology

• Water Trapping Technology