NOA 60HS

NOA 60HS

Seeing is believing.

NOA 60HS

Seeing is believing.

DOWNLOAD DOCUMENTATION

OVERVIEW

NOA - Nippon Paint Marine's unique, self-indicating technology

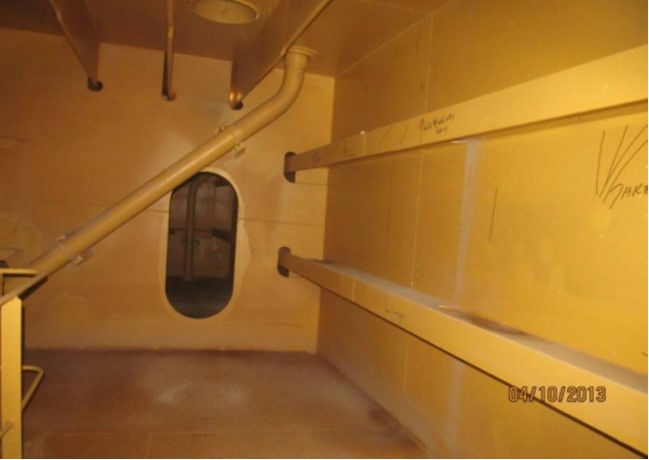

Ballast tanks are the skeleton of the ship. SI technology ensures thickness and protection. NOA60HS complies with IMO-PSPC.

NOA 60HS is the dedicated version of NOA designed especially for use in ballast tanks, cargo oil tanks and voids. For narrow and confined spaces, accurate application of correct thickness of coating is essential. With NOA. Seeing is believing.

Key Features

Long-term corrosion protection, anti-abrasive performance

Reduction in inspection and maintenance

Flexible coating, resistance to cracking. Pinhole free formulation

FEATURES

Self-Indicating Technology

- Self-Indicating Technology works during application. The sprayer can judge thickness by colour as they work.

- Paint application, even in the dark is more accurate with NOA

- On edges and corners ; low film thickness can be seen, enabling the yard and painter to correct and build up thickness.

- NOA is a film thickness controller.

Pinhole free formulation

NOA60HS has special pinhole free formulation. Nippon Paint Marine’s chemists achieved this by carefully balancing and adjusting the paint formulation

Delay of drying time

NOA’s drying time was optimised to balance the surface drying with the release of bubbles and solvent from within the coating.

| DFT 100µm | DFT 300µm | DFT 600µm | DFT 900µm | |

| NOA 60HS | 33min. | 73min. | 85min. | 92min. |

| Current epoxy paint for WBT | 16min. | 35min. | 40min. | 43min. |

Viscosity control

NOA60HS’s Viscosity control was optimised by Nippon Paint Marine’s chemists in order to achieve optimum results. NOA60HS has better holdup and self-levelling properties than other epoxy coatings for ballast tanks. NOA60HS has a very uniform and smooth final coating. Improving the viscosity of NOA60HS ensures excellent wettability. This ensures perfect coverage and adhesion.

APPLICATION

66 months after application

32,739 dwt Bulk Carrier (delivered in Mar 2005)

Good condition confirmed in topside tanks

59 months after application

312,423 dwt VLCC (delivered in Oct 2008)

No rust & corrosion observed

60 months after application

18,758 dwt Vehicle Carrier (delivered in Sep 2008)

Good condition without corrosion

120 months after application

11,179 dwt (920 TEU) Container (delivered in Jun 2005)

No rust & corrosion observed

120 months after application

80,920 dwt LNG carrier (delivered in Oct 2004)

Degree of rusting : below 0.01% of total coating areas

CERTIFICATION

NOA60HS series complies with IMO PSPC-WBT & PSPC-COT. Certification from Classification Societies is available.

ClassNK, – DNV-GL, – American Bureau of Shipping, – Lloyd’s Register

Bureau Veritas, – Korean Register

NOA60HS series is qualified by NORSOK M-501 (ISO12944)