NOA PC700

Novolac Epoxy (Tank Coating System)

NOA PC700

Novolac Epoxy (Tank Coating System)

DOWNLOAD DOCUMENTATION

OVERVIEW

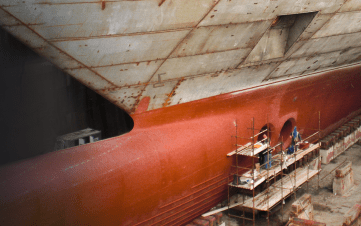

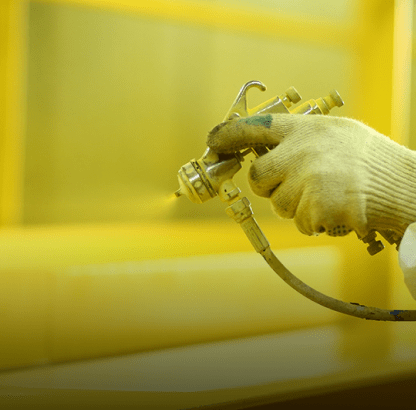

NOA PC 700 is a phenolic / novolac epoxy coating designed for cargo oil tanks loaded with petroleum and chemical products.

It offers superior resistance to petroleum products, solvents, water and chemical attack. NOA PC 700 protects cargo oil tanks from corrosion and prevent cargoes from contamination. NOA PC 700 proves easy to clean during operation.

Key Features

Resistance to impact, corrosion, chemical, and water.

Reduction in inspection and maintenance

Fewer dry spray. Good workability.

FEATURES

Proven Protection - PSPC Test

| Test parameter | Acceptance criteria | Test Results | Evaluation |

| Water resistance | No blisters No rust | No blisters No rust | Passed |

| Pinholes | 0 | 0 | Passed |

| Adhesion | >3.5Mpa | 6.1Mpa | Passed |

| Cathodic disbondment | <8mm | 1-2mm | Passed |

| Undercutting | <8mm | 1-2mm | Passed |

| U-bar | No defects | No defects | Passed |

| Cargo resistance | No blisters No Rust | No blisters No Rust | Passed |

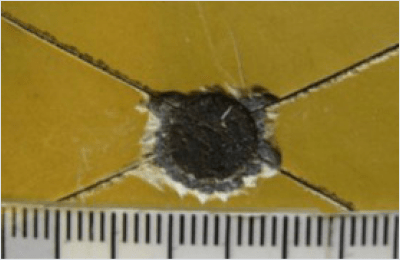

Cathodic disbondment

Disbondment from artificial holiday: 1-2mm

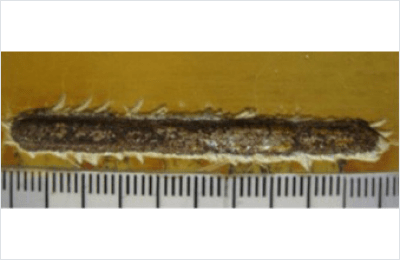

Undercutting

Undercutting from scribe: Ave 2.7mm

Cargo resistance

No blisters or rust

Wide range of cargoes

NOA PC 700 is applicable to various types of cargoes.

| Cargo | NOA PC 700 | NOA PC |

| LSA fuel oil | Acceptable | Acceptable |

| Xylenes | Acceptable | Acceptable |

| Methyl ethyl ketone | Acceptable | Non acceptable |

| Methanol | Acceptable | Non acceptable |

| 45% Caustic Soda | Acceptable | Acceptable |

Nippon Paint Marine has developed a special epoxy phenolic / novolac tank coating system “NOA PC 700”

- Protection of cargo tanks from corrosion.

- Maintenance of ship’s structural strength.

- Protection of the cargo(es) from contaminants.

- Maintenance of the cargo’s quality.

- Easy tank cleaning.