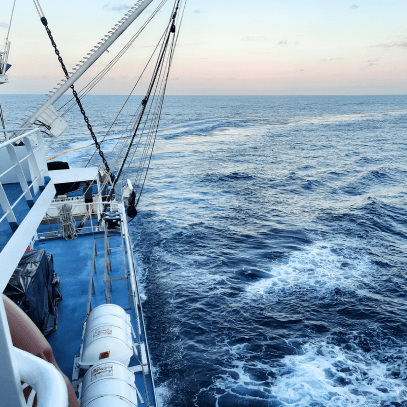

Coating solutions for FISHING boats

For fishing boat operators and boat coating professionals

Coating solutions for FISHING boats

For fishing boat operators and boat coating professionals

OVERVIEW

Nippon Paint Marine's coating solutions for fishing boats is suitable for DIY or professionals.

Excellent antifouling ensures extended operational life and protection of your investments. Our products can be used on fibre-reinforced polymer (FRP), wood or aluminium on your fishing boat. With ease of application and wide product line-ups, our solutions caters to small fishing boat operators and also professionals alike. Our coating solutions always have the environment in consideration.

FISHING BOAT FRP

Outstanding antifouling performance

Since its launch in 1979, Nippon Paint Marine’s “Unagi Toryo Ichiban” has been synonymous with all self-polishing paints in the FRP small fishing boat market. Offering outstanding antifouling performance since then, and remaining the top lank paint over time, it is a reliable partner for fishing boat owners.

Wide product line-ups for FRP fishing boats

For small FRP fishing boats owners, fouling of the ship’s bottom, which may occur during the mooring period, which is always a concern. Nippon Paint Marine has a lineup of products that can be selected according to animal antifouling, vegetable antifouling, pollution status (region), and fuel efficiency considerations.

Environmentally friendly and safety

The product lineup is designed to meet the needs of each customer. Nippon Paint Marine has been actively communicating with the local fishing boat community for a long time, and at the same time, we have been developing and providing products while taking the environment into consideration. Our products are not only based on the performance of the paint, but also on a total balance of workability, efficiency, economy, and safety, ensuring an enjoyable fishing life for our customers.

Products for FISHING boats

Bottom ship paint

| Paint for fishing boats | Ship Material | Degree of pollution in the water area used | |||||

| FRP | Wood | Aluminium | High | Low | Fresh water area* | ||

| UNAGI ICHIBAN

| ||||||

| UNAGI LF-SEA

Blue is navy blue when painted, but changes to light blue after submersion. | ||||||

| UNAGI AZAYAKA NEO

| ||||||

UNAGI AZAYAKA SUPER

| |||||||

UNAGI AZAYAKA RAINBOW

| |||||||

| JUNPU

| ||||||

| MANPAN

| ||||||

* A fresh water area is a water area such as a river with little (or no seawater) seawater.

| For propeller alloys | Type | Capacity | |||||

Tommy’s Propeller Kit | Super water repellent antifouling coating system | 1 box | |||||

Hull Paint

| Product Name | Type | ||||||

| FRP MARINE

| Single pack finish Capacity: 4kg 2kg 1kg | |||||

SUPPORT

Frequently asked questions

"I'm in trouble!" "What should I do?" We will answer the questions you have received.

ABOUT SHIP BOTTOM PAINT

In general, it is difficult to produce complete “pure white” with paint, and the “white” of ship bottom paint is slightly tinted.

For example, the cruiser rainbow “white” is strictly “milky white”, which is a little darker than white like drawing paper. In the case of UNAGI’s “white”, it is gray when painted due to the copper contained in the antifouling agent, but it becomes somewhat white when soaked in water.

The fact that wasabi is effective in preventing marine deposits is actually the result of research by Nippon Paint Marine.

However, if you only need to add wasabi, there should be a paint that contains wasabi from the beginning. However, there is currently no such paint. This is because it is difficult to commercialise it due to the problems of maintaining antifouling power for a long period of time, paint price, and insufficient adhesion between paint films. For that reason, we do not recommend adding wasabi to the paint.

This is a phenomenon that occurs in areas where hedro is accumulated on the seabed. Hydrogen sulfide emitted from the seabed reacts with cuprous oxide contained in the ship’s bottom paint to form copper sulfide, which causes blackening. Hedro tends to accumulate in places where there is no or little tide in the city where domestic wastewater tends to accumulate, so as you asked, it can be said that it is a phenomenon that often occurs in some areas.

If it turns black, the antifouling effect of the ship bottom paint will be lost, so it is best to apply a paint that does not contain cuprous oxide (eg UNAGI Rainbow) to the ship bottom paint.

Alternatively, you can wipe it with thinner and repaint it, or if the area is heavily polluted, increase the number of coats.

If you put the special thinner on the surface of the paint and store it with the lid completely closed, it can be used for about 12 months. When using it again, stir it well from the bottom of the can before using it.

If it is the same manufacturer and the same product name, it is generally possible, but in that case, please consult the manufacturer.

CHOOSING THE SUITABLE PAINT

There are two types of ship bottom paint: a self-consumable type that prevents the adhesion of animals and plants while the coating film itself dissolves when it is submerged in water, and a high hardness type that prevents the adhesion of animals and plants by seeping the antifouling agent between the coating films.

Consumable paints are very effective for boat mooring at sea (for antifouling properties). The high hardness type cannot take advantage of it. Since high-hardness type paint does not dissolve, unnecessary paint film tends to remain, and it is necessary to remove the previous paint with a ship bottom paint remover every time it is applied or every few years.

The advantages of using high hardness paint are power boats that always run at 30 knots or more, racing yachts, diving boats, etc.

Currently, most ship bottom paints contain cuprous oxide as an antifouling agent, but when they come into contact with metal parts, they do cause electrolytic corrosion.

There are also ship bottom paints that do not contain cuprous oxide (UNAGI rainbow), but these have less zinc reduction, but their antifouling properties are slightly lower than those of copper oxide-based paints. Besides, it can be said that zinc protects against electrolytic corrosion, so it is natural that zinc decreases.

Depending on the product, the type of antifouling agent may be different for each colour in order to maintain the hue.

Currently, the mainstream antifouling agent for ship bottom paint is red copper oxide, so it is easy to use for red paint, and it can be said that it is easy to give strong antifouling property to red paint.

If the bottom paint is exposed to the air for too long (eg, 3-4 months or more), the paint’s performance may deteriorate or the painted surface may crack.

From this point of view, especially from the viewpoint of aesthetics, we recommend paints that do not dissolve rather than paints that dissolve on land (such as UNAGI).

PAINTING

The surface of the FRP surface, which was shiny at the time of the new boat, will gradually deteriorate over the course of 5 to 10 years. “Hull paint” and “Outer panel paint” are used to remake it cleanly.

For land storage, apply this “outer panel paint” to the entire surface including the bottom of the ship. At this time, if any paint on the bottom of the ship remains, remove all the paint and then apply the “outer panel paint”.

If you are mooring at sea, paint the bottom of the ship and paint the hull with “outer panel paint”.

Note: If the “outer panel paint” inadvertently adheres to the painted surface of the bottom of the ship, the antifouling effect will be reduced, so be sure to guard it properly with a vinyl sheet or newspaper before painting.

For meltable types such as “UNAGI” and “UNAGI Rainbow”, applying 3 times will make the paint film thicker and will last longer. However, please be sure to observe the amount to be applied at one time and the drying time for each application.

On the other hand, with insoluble paints, the antifouling effect is limited, so there seems to be little difference between two coats and three coats.

However, when painting the bottom of a ship, the “film thickness” is important, not the “number of coats”, so be sure to apply the specified amount even if the number of coats increases a little.

In the case of ship bottom paint, it depends on the thickness applied at one time, but the thicker the paint film, the easier it is to peel off. This is especially true for high hardness paints.

If the paint film peels off and the surface becomes rough, the speed will be adversely affected. It is recommended to remove the old paint with a ship bottom remover, sanding, etc. every 4 to 5 years.

It is most effective to apply it one month before the breeding season of barnacles and green algae (see the breeding season table here).

Specifically, we recommend around May to June for measures against animals such as barnacles, and around September to October for measures against plants such as green algae and slime. In addition, since the paint does not like the humidity caused by rain and the paint film does not dry easily during the rainy season, it is appropriate to avoid the rainy season and apply the first paint around May and the second paint around October.

When painting a new boat, or when removing all the old paint film or repainting, be sure to roughen the FRP substrate with paper before painting the bottom of the boat. The paint on the bottom of the ship will adhere more easily. Applying a primer will make it easier to adhere.

Also, if there is a part that comes off when repainting, be sure to completely remove that part with a scraper or the like.

Wear hats, goggles, gas masks, gloves, etc. as needed.

ABOUT OTHER PAINTS

Apply the rust preventive primer “MARIART P 200” to the undercoat. The recommended number of coats is 4 times. To prevent rust on metal parts, apply the undercoat firmly and repeatedly. The more times you paint, the longer the effect of the topcoat bottom paint will last.

Moisture has entered the bottom of the FRP due to long-term mooring. Blisters are also called “blisters”. The phenomenon of blister formation is called “osmosis”. We will inform you of the measures against osmosis separately. Please contact us if you wish.

Commercially available set nets and “antifouling paints for fishing nets” for aquaculture nets are effective.

That is Nippon Paint’s “Nippe Amitaro”. Please contact us for details.

OTHERS

Basically, when repainting, you need to pay for the ship’s uplift plus the cost of the UNAGI paint.

If you ask a contractor, the painting fee will be on.

However, prices vary depending on the vendor and mooring location, so please contact a contractor for details. When leaving it for the first time, it is recommended to check the paint type / amount used / duration of effect.

As a first aid, wash your eyes with plenty of water and see a specialist.

The same applies not only to the bottom paint but also to other paints and thinners, so when painting, wear goggles, hats, military hands, masks, etc. for safety, and the paints and thinners may get in your eyes or come into direct contact with your skin. Please be careful not to do it.

Wash the brush with the special thinner of the paint used, and when the brush is sufficiently loosened, dry it and store it. Dispose of paint cans as industrial waste.