OMER DADAYLI

QUICK STATS

| Vessel Owner | SPU SHIPPING |

| Location | Shin Kasado Dockyard Co., Ltd., Japan |

| Vessel Type and Tonnage of Vessel | Bulk Carrier/63,733 MT |

| Type of Application | Newbuilding |

| Products | FASTAR XI |

| Applied Vessel Area | Flat Bottom and Vertical Bottom |

| Date of Application | 2023 |

HEAR FROM OUR CUSTOMERS

Following the application of new FASTAR XI hull coating at the new building of our vessel, she spent nearly two months in the tropical waters of the Amazon river. Expecting hull fouling, we arranged for divers to clean the hull, only to find it spotless. The hull was pristine, as if freshly painted.

This exceptional result highlights the superior performance of Nippon Paint Marine’s anti-fouling paint.

Congratulations to the team for setting such high standards in maritime coatings!

Mr.Hüseyin Ozanlı

SPU SHIPPING

PROJECT DETAILS

Nippon Paint Marine applied FASTAR XI when SPU Shipping’s bulk carrier, the OMER DADAYLI was built in Shin Kasado Dockyard Co., Ltd., Japan. Our FASTAR product range provides reliable, low-friction self-polishing technology and superior antifouling performance compared to conventional SPC antifouling technologies, in some of the world’s most volatile conditions.

THE CHALLENGES

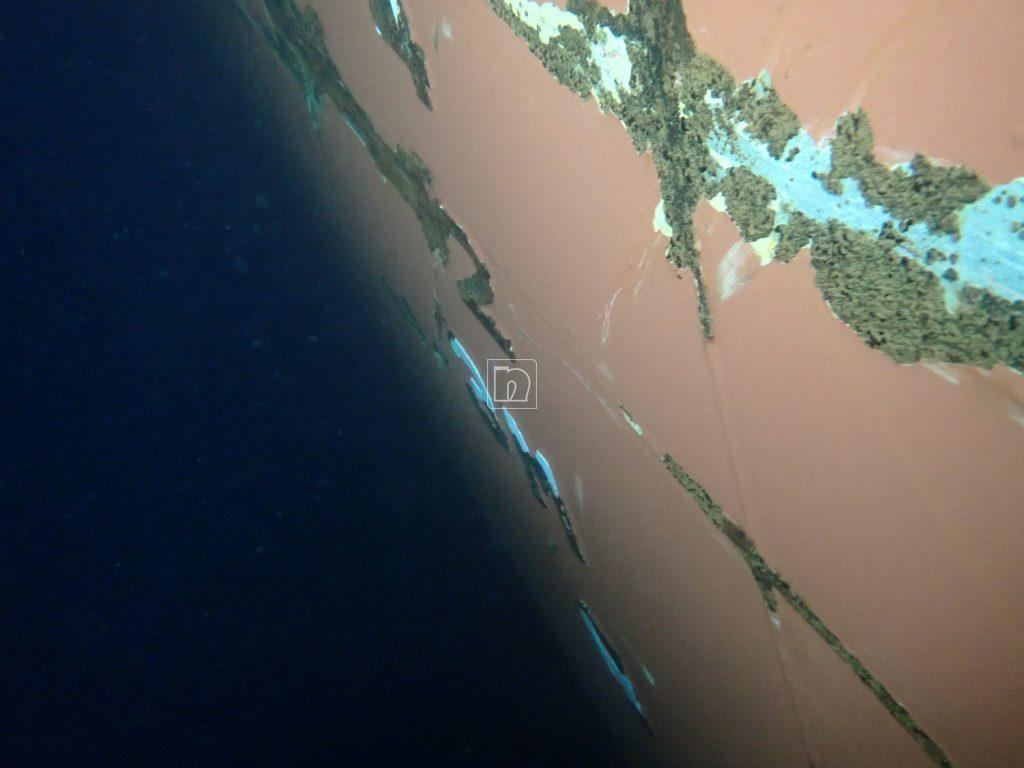

Due to decreasing water level in Amazon River, the vessel underwent an extended period of inactivity at anchorage. After a long period anchored in the Amazon River, in waters that exceeded 30 degrees in temperatures, the vessel moved to Algeciras, Spain. Following this period of inactivity, the client had to carry out underwater cleaning, as per the agreement with the ship owner.

THE RESULTS

After the underwater inspection, the client observed that there was no need for further underwater cleaning maintenance due to clean results. With the application of FASTAR as an antifouling solution, the vessels did not experience any hull foulling even after a long period of time in such warm water conditions.